17/01/2024

Workshop and stoker: A dream of many men.

It was always your dream! At some point, you put it on hold and curbed your creative urge. What happened?

As a passionate craftsman, do-it-yourselfer, DIY expert, and enthusiastic hobbyist, you, like many others, are faced with the problem that your workshop is too cold in the fall. Icy cold in the workplace affects cold fingers and thus your manual dexterity. Too cold to retreat to the "man cave" from the stress of everyday life. Cold temperatures not only make you freeze, but also the materials. Chemical and biological agents, paints, and varnishes require certain temperatures to be processed optimally. As a hobby craftsman, you do not have properly insulated work spaces. For private use, extensive renovations or conversions are not worthwhile. Especially not if it is up to your wife. You are glad that you at least have the right tools. Now, as a hobbyist and tinkerer, you are reaching your limits. You put planned projects on hold during the cold winter months, even though there is plenty of time for your creative urges.

….a warm workshop in winter!

But you can also use simple and inexpensive means to create more warmth and comfortable working temperatures in your workshop and pursue your passion.

Your mission: find out…

1. Where is it coming from?

Find out where the drafts are. In many cases, drafts can be reduced with simple means. So-called draught excluders are quick to make. Let your creativity run wild. Make draught excluders and "windbreaks" out of thick fabric, carpet weave, or use professional PVC strip curtains.

2. Cold floor - cold feet

The subtle difference. Don't underestimate the cold beneath your feet. It creeps slowly but steadily up from beneath you. Insulate your "favorite spot." Place rubber mats where you spend most of your time. These provide ample insulation from the cold, are non-slip, robust, durable, and incredibly easy to clean. They're also soft and easy on your joints.

3. Heat it up properly!

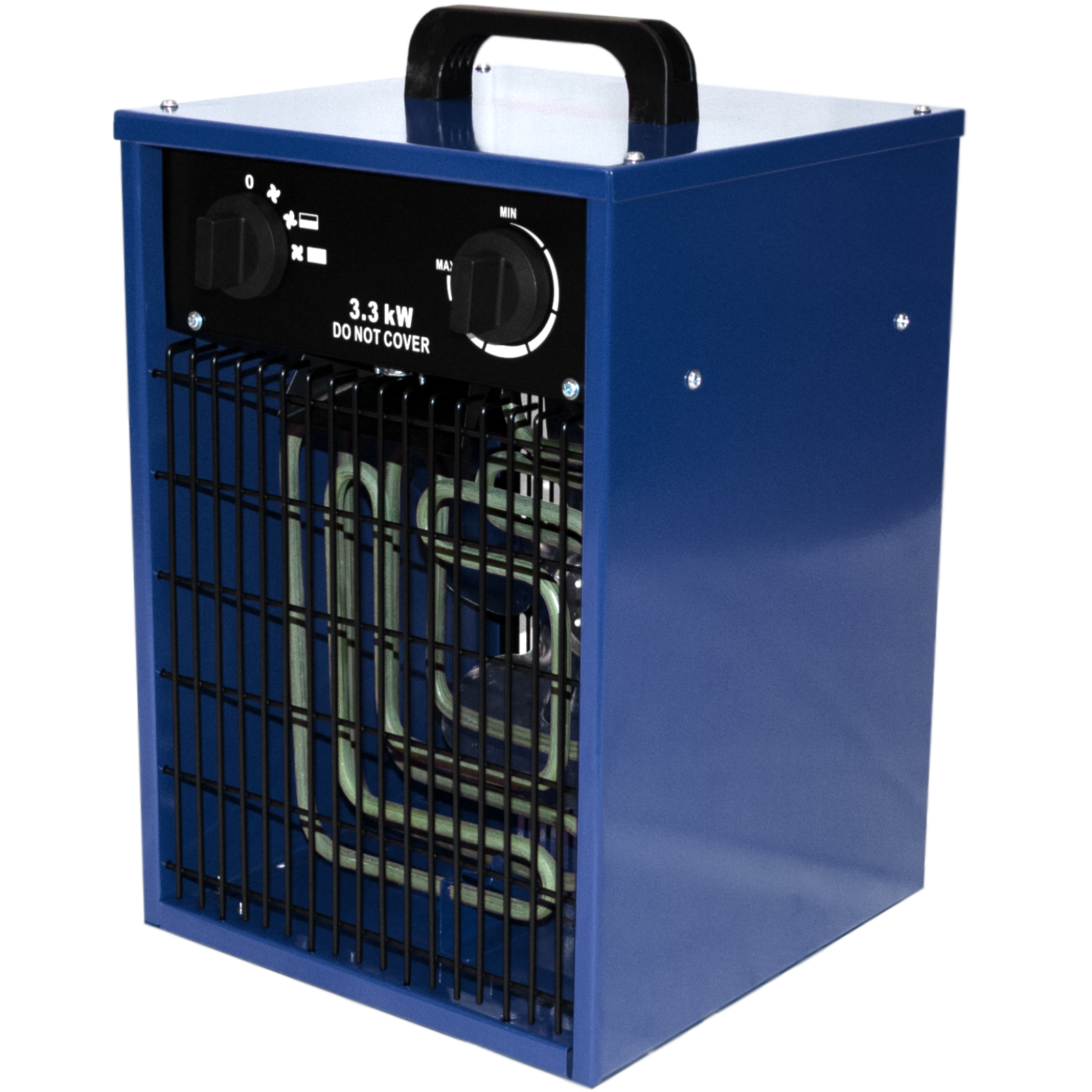

Electric heaters, gas heaters, infrared oil heaters, gas radiators: treat yourself to a compact heating solution for your workshop. Depending on the size and height of your workshop, as well as the specific conditions (insulation, masonry, etc.), there are various models and variants to suit your needs. Click here to see our heaters, and we also offer some tips and advice for heaters – see below.

More tips and ideas for the workshop in winter????

Do you have other ideas for keeping workshops heated and lively during the winter? Share your thoughts and opinions with us. We look forward to receiving your suggestions, contributions, and tips. Feel free to email us at [email protected]!

Heating devices - which device for which needs and with which power?

Basically, heaters can be divided into three broad categories:

Electric heaters are probably the most common heater and the easiest to use. Electrically powered heaters are used in homes, the construction industry, workshops, bars, garages, storage rooms, and even in agriculture. The biggest advantage of electric heaters is that they can be used indoors and (usually) come with a built-in thermostat. The heat output is usually adjustable in stages, and overheating protection is provided by a built-in safety thermostat. Thanks to the 230V connection voltage, electric heaters can be operated "off-grid" almost anywhere there are power outlets. A lot has happened with these devices in recent years, too. While electric heaters were once considered power guzzlers, energy efficiency has increased. However, electric devices still require more input power than gas and oil.

These gas heaters are ideal for drying out buildings, well-ventilated workshops, tents, agriculture, or gardening. They run on propane/butane gas. What's particularly noteworthy here is that the heat output is continuously adjustable and they're the only ones with 100% efficiency. Equipped with a safety thermostat, some units can also be equipped with an optional room thermostat. Since (flammable) gas is known to be rather unpleasant for humans, the necessary ventilation is the only reason these devices haven't already completely conquered the market.

Oil heaters largely share the same areas of application as gas heaters; their direct firing also achieves 100% efficiency. The main difference between them and gas heaters, aside from the fuel, is that some oil heaters also have the option of a chimney, allowing them to be used in enclosed spaces. However, this somewhat increases the purchase price, and of course, a chimney must also provide the option of exhaust air. In recent years, there has also been a new innovation in this area: the infrared oil heater. These do not require a chimney or flue, as the oil burns cleanly and with virtually no residue.

Calculating the required power varies depending on local conditions. A precise calculation must be performed by a local specialist.

However, over time a small “rule of thumb” calculation has been established:

- approx. 110W / m² for new buildings and thermally insulated old buildings

- approx. 180 W / m² for uninsulated old buildings

- approx. 15% surcharge for bathrooms or tiled rooms

- approx. 15% discount for rooms with existing sloping roofs