17/01/2024

Gas springs - how to make them last longer

Source: www.profi.de

When gas springs on cabin windows etc. fail prematurely, it is often due to incorrect handling. We point out the worst mistakes.

Gas springs can be found on tractors and harvesters in a wide variety of applications. But above all on the doors, pop-up windows, hoods, side flaps, steering columns, etc.

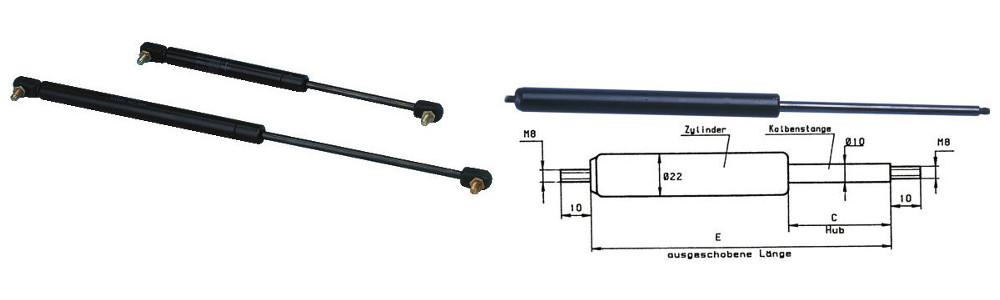

In practice, these high-precision components are often referred to as gas pressure dampers, shock absorbers, gas dampers, etc.. However, the term always refers to the same thing: a cylinder whose piston rod moves out of the cylinder tube at a certain pressure. This pressure must be defined in such a way that, for example, an upright windshield does not collapse but is held securely in position. The correct term for such cylinders is gas spring. In practice, it is often complained that these gas springs, which are not cheap by the way, often fail too soon. The spring effect is then lost, the piston rod is pushed into the cylinder tube without much counter-pressure and a pop-up window, for example, can no longer be held in position.

It is no secret that such a gas spring is subject to a certain amount of wear and tear. However, if the new gas spring is out of order again after a short time, then something is wrong. There can be many reasons for this. In any case, you should make an effort to understand how a gas spring works in order to recognize and avoid serious application errors.

We talked to specialists from Stabilus (a major German gas spring manufacturer) about how to extend the service life of gas springs and what mistakes should be avoided when handling them.

Golden rules for the correct handling of gas springs

1. Install the right way round

Essentially, every gas spring consists of the cylinder tube and the piston rod. There is an ideal installation direction: the cylinder tube must be at the top and the piston rod pointing downwards. Why? Because there is a small amount of oil in the cylinder tube, which has the task of lubricating the piston and the guide or seal package. However, this is only possible if the piston is regularly placed in the oil in the end of the tube facing the inlet opening of the piston rod.

The piston is always located in this area when the piston rod is fully extended.

If installed in the wrong direction, the seals will very soon run dry and increased sealing will occur. As the sealing ability decreases, the spring effect also decreases and the gas spring becomes increasingly slack.

2. Sideways pull is deadly

A gas spring only reaches its maximum service life if it is only subjected to straight-line movements. If it is subjected to lateral tension or is regularly tilted, the internal wear increases rapidly. It is therefore fatal for any gas strut if it is misused as a grab handle, for example. Especially in the area of cabin doors, it is very common for drivers to literally pull themselves up on these cylinders. It couldn't be worse!

3. Flying sparks and welding spatter

Several work steps during production ensure that the piston rod has a super-smooth surface. This is extremely important for maximum sealing effect and minimum wear. This makes it all the more dramatic if flex sparks or welding spatter burn into this surface.

It is therefore essential to ensure that the gas spring is protected during such work. Of course, it is best protected when it is fully retracted.

4. Rough surface due to paint mist

During painting work, flying paint mist can settle on the highly polished piston rod. This also leads to a rough surface, which very soon results in damage to the seal pack. The gas then gradually escapes, the pressure in the cylinder barrel decreases and the gas spring becomes increasingly limp.

It would have been easy to protect the cylinder or at least the sensitive piston rod with a cloth before starting the painting work. Under no circumstances should you protect the rod with adhesive tape. Adhesive residue would roughen the smooth surface. It is safest to remove the cylinder.

5. Anti-twist mounting

6. Do not grease the piston rod

Some practitioners who mean well are of the opinion that the gas spring piston rod should be greased regularly. Well meant - but not good for the gas spring. The layer of oil or grease causes dust to adhere to the piston rod, which can then damage the sealing package when it is retracted into the cylinder barrel. Scoring on the highly polished rod would also be the inevitable consequence. This is because grains of sand get stuck in the seals and then rub against the rod every time the gas spring is extended or retracted. And because this always happens at the same height, a deep groove soon forms.

7. No continuous movements for the gas spring

8. Always replace gas springs in pairs

9. Correct storage

How a gas spring works

A gas spring is a pneumatic adjustment element. It uses glass (usually nitrogen), which is under high pressure, to provide a spring force. Similar to a hydraulic cylinder, the gas spring consists of the piston rod with the piston and the outer pressure or cylinder tube. Depending on how much gas is filled into the cylinder tube, this results in a preset internal pressure, which for most gas springs is between 150 and 200 bar.

The force required to push in the piston rod naturally also depends on the cross-section of the piston. A large piston has a lot of gas pushing against it, which means that a greater insertion force is required than with a small piston. In most cases, the difference can be recognized by the cross-section of the cylinder barrel.

When the piston rod is pushed in, the volume in the cylinder tube is reduced and the gas is compressed. This results in an increase in force. During insertion, gas enters the chamber of the cylinder barrel, which is located above the piston, through a tiny compensating bore in the piston or an equally small groove in the wall of the cylinder barrel. This is the area around the piston rod, the so-called ring chamber. Gas equalization thus takes place.

If the piston rod is not pushed in by hand or by closing an installation window, it will automatically push out of the cylinder barrel again and again. This is simply because the piston area in the pressure chamber of the cylinder barrel, i.e. below the piston, is larger than above the piston in the ring chamber. (This is ultimately reduced by the cross-section of the piston rod.) Incidentally, the small amount of oil in the cylinder has nothing to do with the forces; it serves exclusively to lubricate the sealing elements.

You can find all products here: Gas struts!