Product information "Compressor 703/100 P"

Maximum, robust equipment and best quality at an affordable priceFully automatic on/off operation

With all safety devicesCompletely ready for connection, quality electric motor

Quality electric motor with high starting torque is equipped with a motor protection switch

Starting capacitor and starting relief valve ensure easy starting

With phase inverter as standard for easy manual reversal of the direction of rotation

Compressed air compression via high-performance HOS unit

The start-up relief valve ensures easy and unpressurized start-up

The two-cylinder high-performance unit made of gray cast iron and the low speed guarantee particularly quiet and low-vibration operation and a long service life

This ensures an even longer service life due to even less wear and tear

High-quality compressor with optimum lubrication for a long service life and high reliability

Equipped with high-quality intake filter

The aftercooler with large cooling fins ensures a low boiler inlet temperature and therefore less moisture in the compressed air, which protects the compressed air tools

Additionally with intercooler to the aftercooler

Corrosion-free valve plates for improved heat dissipation and compressor longevity

The large fan wheel and a cooling air baffle on the cylinder ensure optimum cooling of the compressor

A sturdy metal belt guard ensures optimum protection of the components and a high level of user safety

Compressed air supply to the boiler via flexible armored hose line with heat protection prevents vibration breakage

High-quality drive belt

Powerful and economical drive

The toothed drive belt makes starting easier, improves smooth running and power transmission and reduces power consumption by up to 30%Sturdy metal belt guard

Operation on the maintenance block

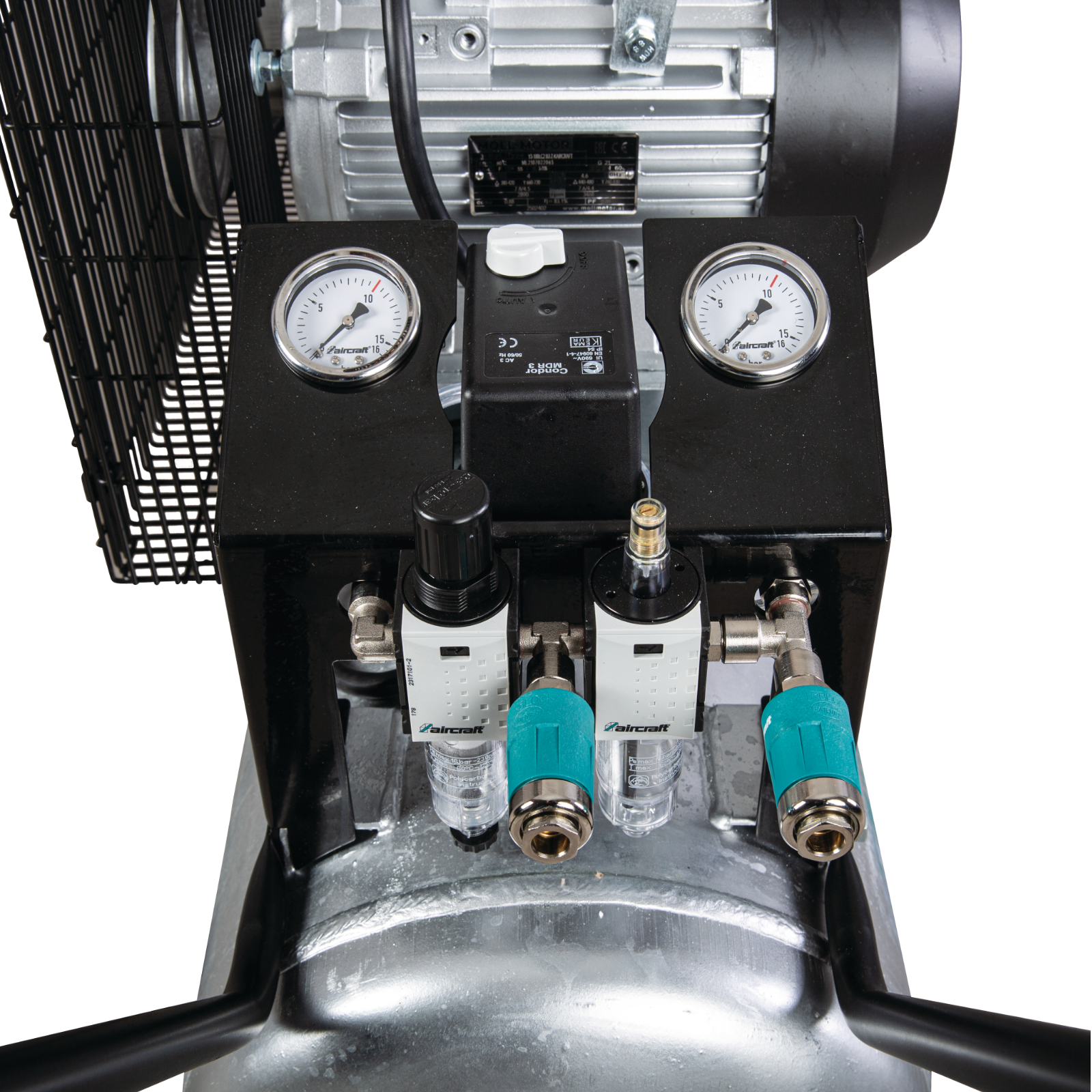

Equipped with a high-quality CONDOR MDR 5 pressure switch with robust push-button function for fully automatic on/off operation

Filter pressure regulator for infinitely variable adjustment of the working pressure, with simultaneous dirt, oil and condensation water separation

Two large pressure gauges indicate the tank and working pressureAir tapping at the maintenance block via a convenient safety quick-release couplingOn the maintenance block only fixed screw connections, no hose connections

Two compressed air tapping points

One compressed air outlet for filtered compressed air

One compressed air extraction point via direct outlet on the boiler with ball valve

Comfort safety coupling - The advantages.

Comfort safety couplings from AIRCRAFT are the first manufacturer to use them as standard

Two separate locking systems for maximum work safety

Dangerous whipping of the hose line is prevented

Comfortable and safe to transport and set up

Ergonomically extended handle for comfortable transportation in an almost upright position - strain on the back due to lifting is avoided

Puncture-proof PU foam wheels and stable steering chassis with parking brake enable easy transportation

The parking brake prevents both turning and rolling movements of the wheels and ensures that the compressor stands perfectly still

With practical second transport handle on the tank, which makes it easier to carry the compressor

High-quality tank with durable rust protection

AIRCRAFT is the first manufacturer to equip the AIRPROFI series compressors with hot-dip galvanized boilers inside and out as standard

The AIRPROFI series boilers therefore come with a 15-year guarantee against rusting through.